Large-sized Machines

Large-sized Machine Manufacturing Technology

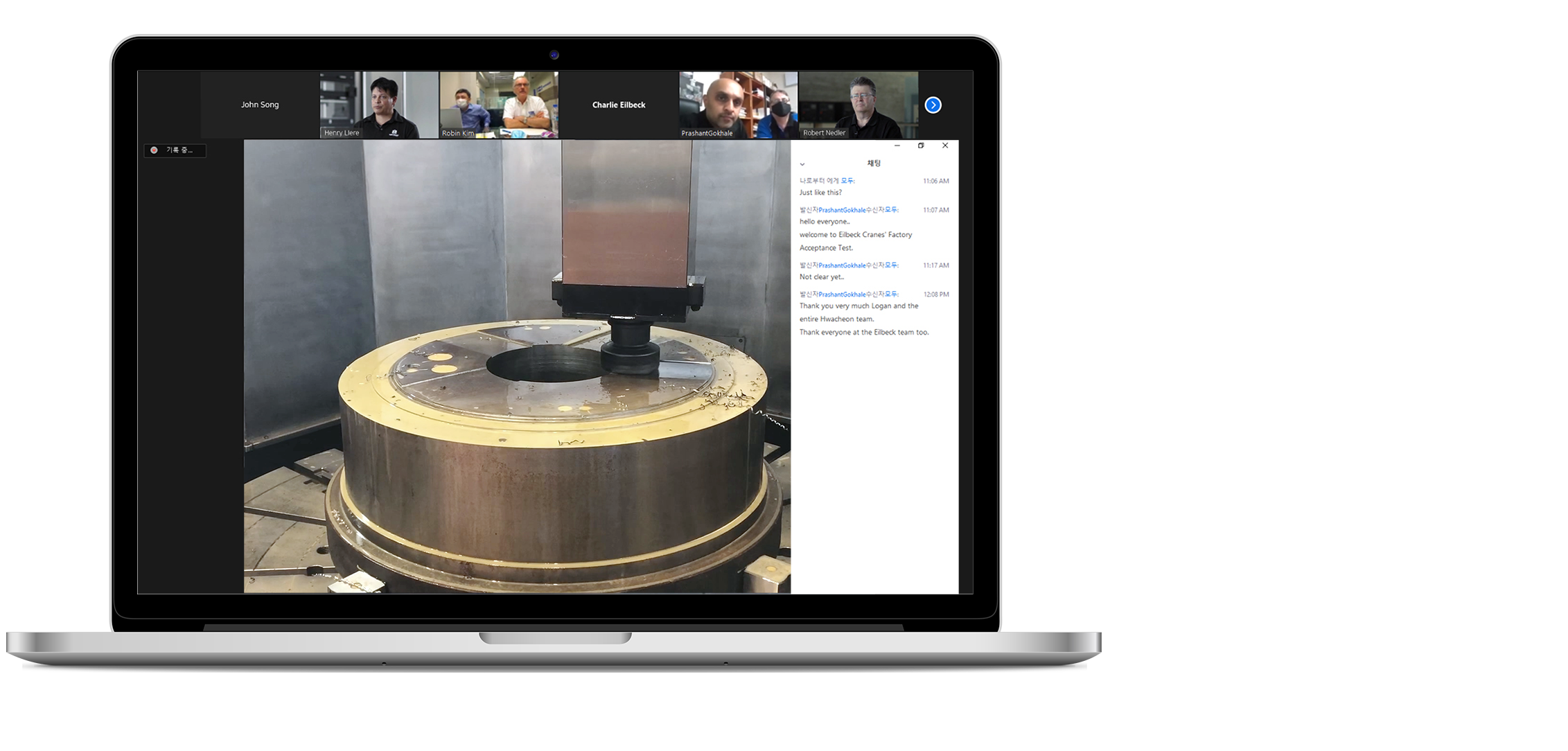

Hwacheon is developing and producing large-sized machine tools used in shipbuilding, plants, aircraft, power generation facilities, and energy industries with its own technology based on machine tool manufacturing technology accumulated for over 75 years.

Achieved Vertical Integration of Machine Tools

Hwacheon is the only company in Korea to produce core items such as machine tool raw materials, castings, spindles, tables, etc., enabling the best quality, rapid development, and service response.

We start with the main

Casting technology and raw materials

The basic performance of a machine tool depends on the casting. Hwacheon’s casting technology, which started with a passion for the highest quality products, insists on the best raw materials. In particular, it is the first in Korea to develop and mass-produce cast products for robot frames and export them to all over the world.

We never compromise the quality

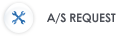

In-house production of core parts

Hwacheon develops and produces spindles the core technology of machine tools, according to the characteristics of the machine. In addition, the best quality, rapid development and service response are possible through our own technology for major parts such as tables, gears, chucks and rotary tables.

Adopt of highly reliable parts

The difference increases over time

It maintains the best product condition even after a long time by adopting only reliable brand parts for parts such as ball screw, LM guide, and air seal.

Customized Large-sized Machines

Perfect for your work piece

Large machine tools require a high level of manufacturing and assembly technology, and customized design and customer-oriented service are important to customer requirements. Hwacheons’ large sized machine tool R&D team meets even the most demanding requirements of customers through close communication with customers from the initial stage.

Pre-consultation, till we know all you need

Through a pre-consultation before production, we provide optimal solutions according to the need of each customer.

Machines are manufactured through a step-by-step internal inspection process, designed to be customized considering the quality and convenience to ensure longer lifespan.

Whenever and Wherever

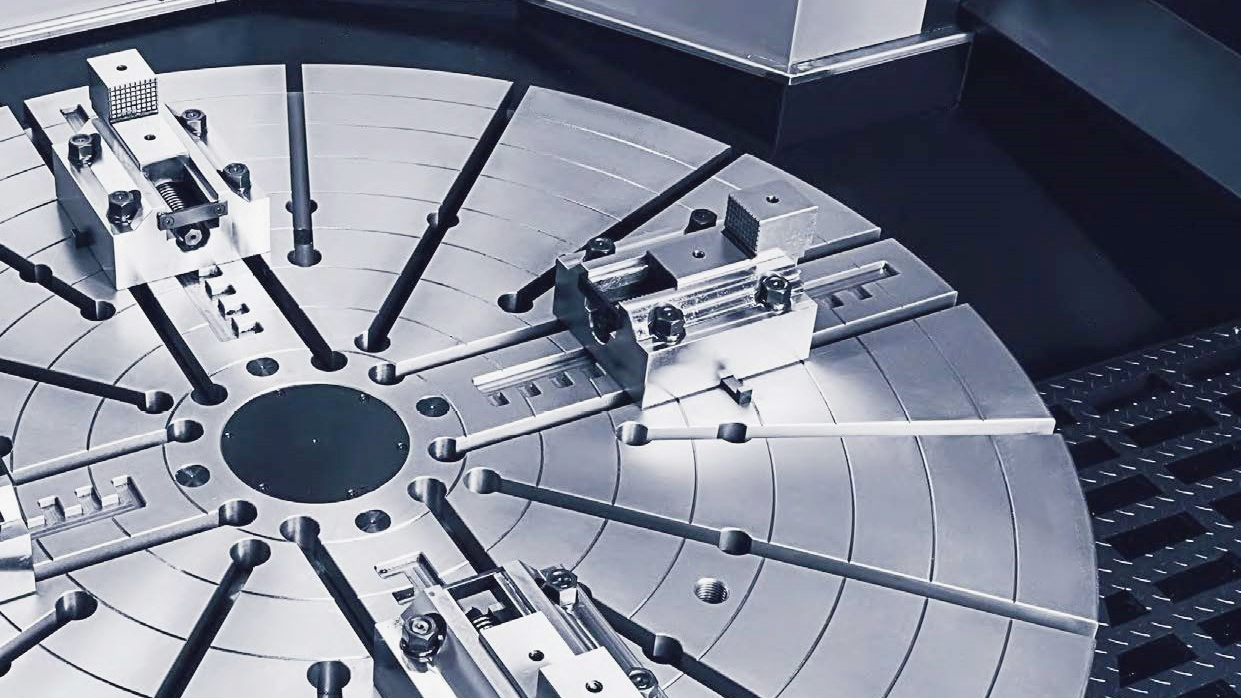

On-line Inspection is possible

We gain trust from customers by transparently sharing the machine production progress upon customers’ request.

Pre-shipment on-line Inspections are available in order to share the machine performance test results by video in case the customer cannot make a physical trip to Hwacheon factory.

Anytime, we will be there

For your service

With Installation & Commissioning including the training of users, customers are able to operate the machine in a more efficient way.

Through performance check/diagnosis on a regular basis, the quality of the machine can be maintained even after a long-period of use.

-

As an innovation leader in the industry with more than 7,000 employees

-

On the following pages you can obtain information about the nume