Software

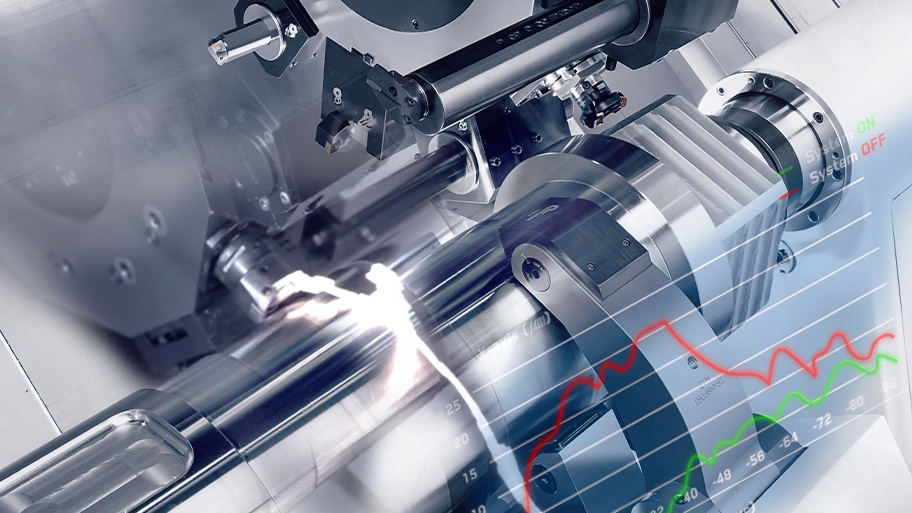

Transcending Limits with Perfect Machining Hwacheon Software

The word "software" may sound ordinary, but within it lies cutting-edge IT technology and more than 75 years of machining expertise accumulated by Hwacheon.

Hwacheon software replaces the intuition and experience of skilled technicians by allowing the machine itself to optimize machining paths and cutting speeds. It also corrects thermal displacement errors in real time and prevents collisions as they occur. This goes beyond the machine's structural capabilities, realizing a higher level of precision and safety in machining.

Machining Optimization

Hwacheon's machining optimization software replaces the intuition and expertise of skilled technicians, allowing the machine to independently analyze the machining environment. This function improves both machining quality and productivity.

Simulation and Real-time Collision Prevention

By running machining simulations that precisely match actual operations, the software verifies NC data before machining. The machine also automatically halts just before a potential collision, preventing damage to both the machine and tools, ensuring safe machining processes.

Monitoring and Machining Management & Analysis

Monitor the operating status of machines, alarm occurrences, and machining completions in real time, no matter where you are. By analyzing the machining history by machine and operator, the software accurately diagnoses machine utilization and productivity.

-

As an innovation leader in the industry with more than 7,000 employees

-

On the following pages you can obtain information about the nume